- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

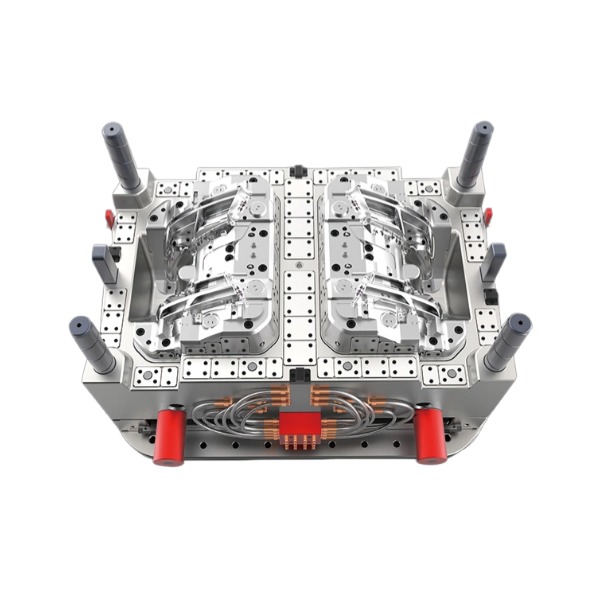

In modern vehicle manufacturing, automotive molds are crucial for producing high-quality parts. The advent of 3D injection molding has transformed this process, offering efficiency and precision.

In this article, we will explore the role of automotive molds in the automotive industry. You’ll learn about the advantages, costs, and future trends surrounding 3D injection molding technology.

An automotive mold is a specialized tool used to shape materials into parts for vehicles. These molds are essential for manufacturing a wide range of automotive components, from exterior panels to interior features. The mold itself is typically made of metal and consists of a cavity that gives the part its shape.

Automotive molds ensure high precision and repeatability, crucial for maintaining the safety, functionality, and aesthetics of vehicle parts. The goal is to produce large quantities of identical parts with minimal variation.

The materials used in automotive molds play a crucial role in ensuring the durability and quality of the parts produced. Different materials are selected based on the specific requirements of the automotive parts, such as strength, flexibility, and heat resistance. Below is a summary of the common materials used in automotive mold production and their key benefits:

Material | Properties | Common Automotive Applications | Benefits |

ABS (Acrylonitrile Butadiene Styrene) | High strength, ease of processing | Automotive interior and exterior parts (e.g., dashboards, trim) | Durable, cost-effective, and easy to process |

Polypropylene | Lightweight, durable, impact-resistant | Bumpers, trim, and battery cases | High durability, resistance to chemicals, and flexibility |

Nylon | High strength, heat-resistant, durable | Engine components (e.g., bushings, bearings) | Excellent heat resistance and mechanical strength |

Polycarbonate | Transparency, high impact resistance, and durability | Headlights, tail light housings | Ideal for transparent components and high durability |

Each material is carefully chosen to meet the specific functional and aesthetic requirements of automotive components, ensuring both high performance and longevity.

Creating an automotive mold involves several stages:

1. Design: The first step involves designing the mold using computer-aided design (CAD) software to ensure accuracy and optimal functionality.

2. Material Selection: The right materials are selected based on the part’s intended use and performance requirements.

3. Mold Fabrication: Using advanced manufacturing techniques like CNC machining or 3D printing, the mold is created to the exact specifications.

4. Testing: Prototypes are produced and tested for fit and performance before full-scale production begins.

The integration of 3D printing in this process allows for rapid prototyping, reducing lead times and ensuring high precision.

3D injection molding combines traditional injection molding with 3D printing technology. It starts with injecting molten material into a mold cavity. The use of 3D printing allows for more complex mold designs, reducing the need for multiple traditional molds and tooling.

The process is highly automated, making it ideal for mass production. Components are produced quickly and with minimal human intervention, ensuring efficiency and consistency.

1. Precision and Repeatability: 3D injection molding allows for the production of parts that are nearly identical, ensuring high quality and uniformity.

2. Speed of Production: The efficiency of 3D injection molding enables manufacturers to produce large quantities of parts quickly, helping meet the high demands of the automotive industry.

3. Design Flexibility: 3D molding supports more intricate designs and complex geometries, which are often required for modern automotive components.

Advantage | Benefit |

Precision and Repeatability | Ensures identical parts with high quality |

Speed of Production | Fast production to meet high demands |

Design Flexibility | Enables intricate and complex part designs |

Tip: For manufacturers, utilizing 3D injection molding can streamline production timelines and reduce the need for costly tooling adjustments.

Once a mold is created, 3D injection molding is highly cost-effective for producing large batches of automotive parts. The cost per unit decreases significantly as production scales up. This is one of the primary reasons why injection molding is favored in industries like automotive manufacturing, where large quantities of uniform parts are required.

Automotive molds used in 3D injection molding can accommodate complex designs and intricate features that would be difficult or expensive to achieve with traditional manufacturing methods. This flexibility allows for the creation of lightweight, detailed parts such as dashboard components, exterior panels, and internal mechanical elements, all tailored to the specific needs of the vehicle.

Injection molding is known for its material efficiency. The process minimizes waste by precisely shaping the material to fit the mold, reducing the need for excess raw material. This not only helps in reducing production costs but also contributes to environmental sustainability.

Automotive molds made through 3D injection molding ensure high precision, meaning the parts produced will fit together seamlessly, which is essential for safety and performance. The durability of these molds also ensures that parts can withstand extreme conditions, including heat and pressure.

The initial tooling costs for 3D injection molding can be significant. Creating the first mold requires precise engineering and material selection, which can be expensive. However, once the mold is created, the cost per part decreases dramatically with mass production.

As production volume increases, the cost per unit of each automotive part decreases. This makes 3D injection molding an excellent choice for mass-producing automotive components, as the initial high cost of tooling is spread across thousands or even millions of units.

Complex designs or the need for custom materials can increase the cost of producing automotive molds. While 3D injection molding can accommodate intricate designs, these features may require more advanced molds, which can increase both tooling and production costs.

Cost Factor | Impact |

Initial Setup & Tooling | High initial cost, but decreases with mass production |

Cost per Unit | Reduces with higher production volumes |

Design Complexity | Increased complexity can raise costs |

While 3D injection molding offers flexibility, the initial tooling costs can be a barrier for some manufacturers. For smaller production runs or highly customized components, the cost of creating new molds can be prohibitive. Additionally, some complex designs may still present challenges in achieving the desired quality or cost-effectiveness.

Choosing the right material for an automotive component is critical. Factors like heat resistance, chemical compatibility, and structural integrity must be considered. The material must perform well under harsh conditions, making material selection one of the most important aspects of mold design.

Designing parts for injection molding requires a deep understanding of the manufacturing process. Parts with thin walls, intricate details, or undercuts can be difficult to mold, requiring additional steps in the design phase to ensure manufacturability.

Tip: Engage in early-stage design for manufacturing (DFM) reviews to identify potential issues and optimize the production process.

Automation continues to play a growing role in automotive molding. The use of AI and advanced robotics allows for faster, more efficient production. Smart molding technologies can monitor the molding process in real-time, ensuring consistent quality while reducing human error.

As the automotive industry pushes for lighter, stronger, and more sustainable materials, mold manufacturers are developing new composites and bio-based plastics. These materials offer improved performance and environmental benefits, meeting the increasing demands for fuel efficiency and reduced emissions.

3D printing complements injection molding by enabling rapid prototyping and small-scale production runs. By using 3D printing to produce prototype molds or individual components, manufacturers can quickly test designs and make adjustments before committing to full-scale production.

Trend | Impact |

Automation & Smart Technologies | Faster, more efficient production, quality control |

Advances in Materials | Development of lightweight, sustainable materials |

3D Printing in Manufacturing | Quick prototyping and small-scale production runs |

Automotive molds in 3D injection molding offer significant benefits, such as cost-efficiency, design flexibility, and precision. This method is ideal for mass-producing large quantities of identical parts. However, manufacturers should carefully weigh tooling costs and design challenges.

Looking ahead, 3D injection molding will continue to drive innovation in automotive production. Smart technologies, new materials, and faster prototyping will further enhance this process. Taizhou Huangyan Guangdian Technology Co., Ltd. provides high-quality automotive molds, helping manufacturers achieve precision and efficiency.

A: An automotive mold is a tool used to shape materials into automotive parts. It ensures high precision and repeatability in manufacturing parts like dashboards, bumpers, and engine components.

A: 3D injection molding involves injecting molten material into a mold, combining traditional molding with 3D printing. This allows for complex designs and efficient mass production of automotive parts.

A: 3D injection molding offers design flexibility, precision, and cost-efficiency. It allows for mass production of identical automotive parts with minimal waste and faster turnaround times.

A: Automotive molds in 3D injection molding provide high precision, reduced costs for mass production, design flexibility, and better material efficiency, making them ideal for producing high-quality automotive parts.

A: The initial tooling cost for automotive molds can be high, but costs per unit decrease significantly with large production runs. More complex designs may increase costs, but mass production reduces overall expenses.

A: Yes, automotive molds can be customized to fit various parts, from interior components to exterior panels, ensuring each part meets specific design and performance requirements.